Lyft

Flexible, Fast, and Reliable Corrosion Under Insulation (CUI) Integrity Management Solution.

Eddyfi Lyft® can scan through thick insulation, as well as aluminum, stainless steel, and galvanized steel weather jackets. It also benefits from a range of PECA, single-element PEC, and application-specific probes to support various applications. Who else but Eddyfi to reinvent an eddy current technique and redefine CUI programs?

Benefits

Applications

- Inspect through thick metal and insulation

- Save on insulation removal costs

- Real-time imaging for instant results

- One-touch automated reporting

- Range of application-specific probes

- Fast data acquisition

- Easy setup with automatic optimization of pulser and receiver parameters

- Corrosion Under Insulation (CUI)

- Corrosion Under Fireproofing (CUF)

- Insulated pipes and vessels

- Through aluminum, stainless steel, and galvanized steel weather jackets

- In-service scab corrosion assessment, no need to remove the scale

- In-service inspection of storage tank annular plates

- Underwater and splash zone structures

- Marine vessels

CUI Programs Redefined

Corrosion Under Insulation (CUI) is possibly the greatest unresolved asset integrity problem in the industry. Current methods for measuring wall thickness over insulation (Liftoff) without removing it all have severe limitations. Lyft® is a high-performance solution reinventing Pulsed Eddy Current .

Lyft can scan through thick insulation, as well as aluminum, stainless steel, and galvanized steel weather jackets. It also benefits from a range of PECA, single-element PEC, and application-specific probes to support various applications. Who else but Eddyfi would reinvent an eddy current technique, integrate high-productivity array to the solution and completely redefine CUI programs?

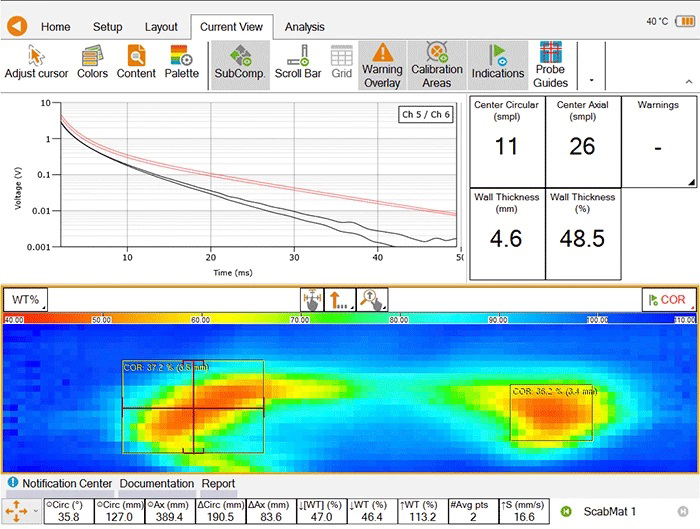

Automated Software for Reliable and Repeatable Results

The Lyft is packed with automation and advanced algorithms that remove operator-specific dependence, thanks to the power of the SmartPULSE™ technology. It automatically optimizes pulser and receiver parameters (gain, duration, time gates, filters, etc.). SmartPULSE also adjusts Wall Thickness (WT) measurements to ensure optimal performance and repeatability, while limiting the need for advanced knowledge of pulsed eddy current. The user-friendly multi-touch software also includes several innovative features, including real-time C-scan imaging (grid-mapping and dynamic modes), complete wall thickness measurements (ID and OD corrosion), as well as complete inspection management and reporting capabilities.

Unique to Lyft—Wall Thickness Measurement Tool for Smaller Flaws

Under sizing is a well-known phenomenon for PEC where defects smaller than the probe’s averaging area appear shallower than they really are. The Lyft’s Compensated Wall Thickness (CWT) tool mitigates the phenomenon by quantifying the minimum wall thickness of a specific region in a C-scan. The CWT tool’s specialized algorithms isolated a defect’s contribution to the A-scan signal to compute its minimum wall thickness more precisely.

Desktop Analysis Software

Lyft PRO enables advanced Lyft data analysis and features the same graphical user interface than the Lyft software, making it easy to learn and benefit from larger data layouts. This translates into Lyft instruments out in the field acquiring data while analysts work hard to extract value from acquired data. Lyft PRO makes it easier to plan inspections for several Lyft instruments. It also has a power mode allowing you to connect your computer to your Lyft instrument and to perform acquisition. Furthermore, the software has features to generate richer reports, tools to bridge calibration parameters between scan zones and take advantage of the Tau-scan™ for advanced analysis of PEC data. .

SurfacePro3D is an advanced visualization and reporting software designed to automatically create components and overlay stitched C-scan data. Use it to import Lyft reports, create 3D components, and stitch color maps automatically. Easily import, export, create and edit report templates. Compile and merge inspection data with associated images, inspection parameters, and defect tables for fast and compelling reporting.

Optimized Performance for Wall Thickness and Liftoff

The Lyft solution includes several sizes of plug-and-play probes for the right balance between wall thickness and liftoff.

The PECA high-productivity probe is capable of a single-pass coverage of 457 mm (18 in) in grid or high-resolution encoded dynamic mode. It supports metal thickness 6–25 mm (0.25–1.0 in), insulation 0–102 mm (0–4 in), and stainless steel and aluminum weather jackets. CUI assessment has never been this fast, improving overall inspection productivity as much as 10 times.

The single-element PEC probe family supports metal thicknesses up to 100 mm (4 in), insulation as thick as 300 mm (12 in), and stainless steel/aluminum/galvanized steel weather jackets. They complement the array probes in limited-access, small-pipe, and thick-component inspections.

Application-Specific Probes

The patent-pending high-resolution PECA probe is designed specifically for the inspection of scabs and corrosion blisters. Using an array of dual sensors capable of spatial triangulation, the probe enables the detection of the smallest possible defects with PEC technology. It supports metal thickness 3–19 mm (0.12–0.75 in), insulation 0–50 mm (0–2 in) and a single-pass coverage of 75 mm (3 in) in dynamic or grid mode.

The tank floor probe enables the in-service inspection of storage tank annular rings. With its 4.8 mm (0.2 in) thick, super-thin titanium blade, the probe can slide up to 400 mm (16 in) under tank floor edges, assessing the remaining wall thickness of this critical region exposed to corrosion. The embedded remote controls and status LEDs are also perfect for one-person operation.

The patent-pending galvanized steel cladding probe (PEC-GS) is specifically designed to improve detection capabilities and sizing accuracy by reducing the footprint dimensions to normal. The design neutralizes the interference from the jacket, improving signal penetration, and prevents vibration for an unsurpassed signal-to-noise ratio.

Splash Zone and Underwater Probes

The splash zone probe can tackle offshore applications, thanks to its rugged design, water tightness to 15 m (49 ft) in grid mode, and 25 m (82 ft) cable. The splash zone probe is flexible enough to support metal up to 76 mm (3 in) thick and insulation or marine growth up to 203 mm (8 in) thick.

Underwater probes can tackle deeper offshore applications. They are watertight down to 100 m (330 ft) and, through the long extension cable, are used with Lyft in grid-mapping mode. The embedded status LEDs ensure better control and synchronization with the topside team. The probes can be used on metal as thick as 100 mm (4 in), as well as insulation and marine growth as thick as 300 mm (12 in).

The Best of PEC in a Portable Instrument

The Lyft instrument is sealed and designed for IP65. Its magnesium alloy casing is tough, water and dust resistant, and cools without any external air exchange. The adjustable stand, the top handle, and four corner anchor points make it practical for on-site inspections. The embedded and portable Windows® PC offers standard connect-anywhere capabilities and advanced productivity tools that optimize field testing. The premium-quality 26.4 cm (10.4 in) LED display is optically bonded, non-reflective, comes with 3 mm (0.12 in) strengthened glass, and is designed for gloved hands, under any lighting conditions. The system also comes with two, hot-swappable batteries for extended battery operation.

Specifications

INSTRUMENTS

Dimension (W × H × D): 355 × 288 × 127 mm (14.0 × 11.3 × 5.0 in)

Instrument weight: 6.6 kg (14.5 lb)

Number of channels: 7 (GA/GDA)

Display: 26.4 cm (10.4 in)

Multi-touch

Non-reflective (AR coating)

Anti-fingerprint (oleophobic coating)

3 mm (1/8 in), chemically strengthened glass cover

Optically bonded LCD and touchscreen

Passive blacklight enhancement

Connectivity: Gigabit Ethernet, Wi-Fi™, Bluetooth®, 3 × USB 2.0

PERFORMANCE

Dynamic data acquisition: Up to 15 points/s

Dynamic scan speed: Up to 75 mm/s (3 in/s)

Grid mapping scan speed: Instant, less than 1 second (typical)

SmartPULSE: Automatic configuration of PEC pulser-receiver parameters

Full thickness sensitivity (OD and ID flaw detection)

Reliable measurements even with liftoff variations, weather jackets overlaps, straps, and corrosion scabs

Repeatability optimization

One-point calibration (on nominal wall or known thickness value) and auto-normalization

PROBES

Features: Remote control keypad

Lyft 27-pin Fischer connector

Heavy-duty 5 m (16.4 ft) cable

Support for universal clip-on encoder

Nominal wall thickness: Up to 102 mm (4 in)

Insulation (Liftoff): PECA-6CH-MED: 0–102 mm (0.4 in)

PEC-152G2: 0–305 mm (0–12 in)

PEC-089-G2: 0–203 mm (0–8 in)

PEC-025-G2: 0–76 mm (0–3 in)

Smallest detectable defect volume: 15% of footprint volume (footprint × wall thickness)

Min. measurable remaining wall thickness: 15% from nominal

Weather jackets: Stainless steel up to 1.5 mm (0.06 in)

Aluminium up to 1 mm (0.04 in)

Galvanized steel up to 1 mm (0.04 in)

Pipe diameters: Down to 25 mm (1 in)

Test temperatures:

Carbon steel structure temperature range: -150–500°C (-238–932°F)

Maximum weather jacket temperature for direct contact operation: 70°C (158°F)

Maximum weather jacket temperature with probe shoe: 120°C (248°F)

APPLICATION-SPECIFIC PROBES