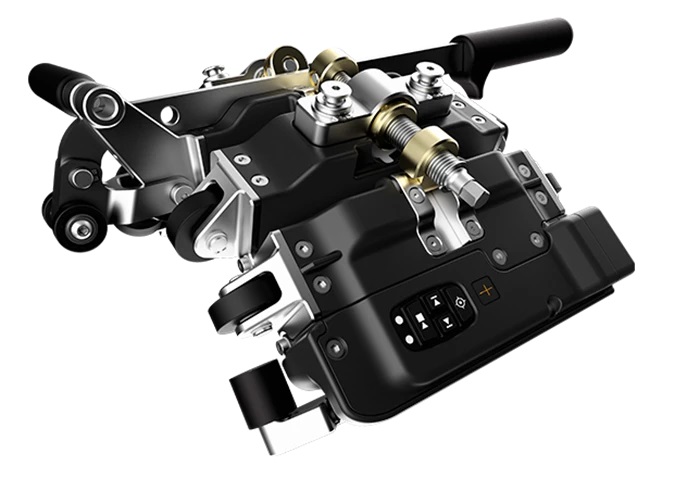

PipeScan HD

The Eddyfi Technologies Pipescan HD solution is designed to maximize speed, reliability, and confidence for the detection of corrosion and pitting in ferrous pipes and surfaces. It increases the total efficiency of integrity assessment campaigns by enhancing the productivity of the inspection team, optimizing the workflow to include on-the-spot reporting, and providing the asset owner with verifiable, recorded data.

Benefits

Applications

- Speed: Scanning, data analysis and reporting in one quick workflow.

- Highest resolution on the market offering easy to understand C-scan imaging.

- High probability of corrosion detection with defects down to 1 mm (0.04 in) identified.

- Simple in-service deployment: No coupling and minimal surface preparation required.

- Easy to operate with minimum training required.

- Flexible heads fit a full range of pipe and vessel sizes.

- Full data recording with adjustable reporting threshold feature.

- Oil & Gas

- Distribution, gathering, feeder or transmission pipelines.

- Manifold lines.

- Dead legs.

- Vessels.

- Jetty lines.

- Condensate terminal pipework.

- Power Generation

- Service water systems

- Fire protection systems

- Coal-fired plants boiler pipes

The Pipescan HD is the highest resolution MFL scanner on the market. With a high Probability of Detection (PoD), the Pipescan HD is an effective and reliable pipe inspection solution for corrosion and pitting detection.

Pipescan deployment is easy with the unique single curvature adjustment tool allowing for a quick inspection setup. No coupling or complicated gate settings are required, connect the Pipescan to the data acquisition instrument, enter inspection details, and the system is ready to go.

Furthermore, all scanned data is automatically recorded, and reports can be issued on the spot, giving asset owners immediate visibility on the health condition of their assets, enhancing productivity and efficiency.

Specifications

General

Technology: Magnetic Flux Leakage / Hall Effect Sensors

Method of Propulsion: Hand Push Speed up to 1 m/sec (40 in/sec)

Coating thickness: Up to 6 mm (0.2 in) nonmagnetic material

OD range (real value): PS-HD-MFL-127XFLAT: 127 mm to flat (5.0 in to Flat)

PS-HD-MFL-73X127: 73 mm to 127 mm (2.875 in to 5 in)

PS-HD-MFL-48X63: 48 mm to 64 mm (1.9 in to 2.5 in)

Recommended wall thickness: PS-HD-MFL-127XFLAT: Up to 12.7 mm (0.5 in)

PS-HD-MFL-73X127: Up to 8.56 mm (0.337 in)

PS-HD-MFL-48X63: Up to 6.05 mm (0.238 in)

Number of channels: PS-HD-MFL-127XFLAT: 27

PS-HD-MFL-73X127: 17

PS-HD-MFL-48X63: 9

Channel spacing: 7 mm (0.27 in)

Smallest detectable defect: Detection from Ø >1 mm and 20% wall loss

Maximum surface temperature: 60°C (140°F)

Connecting cable: 5 meters (15 feet) standard length

Weight: PS-HD-MFL-127XFLAT: 26 lbs (11.8 Kg)

PS-HD-MFL-73X127: 20.5 lbs (9.3 Kg)

PS-HD-MFL-48X63: 12 lbs (5.5 kg)

Transit case: Meets IATA requirements for transporting magnetizable material

Compatible Instruments: Silverwing Swift-M, Eddyfi Reddy-32M