M2M Gekko

Ultrasonic Flaw Detector Phase Array

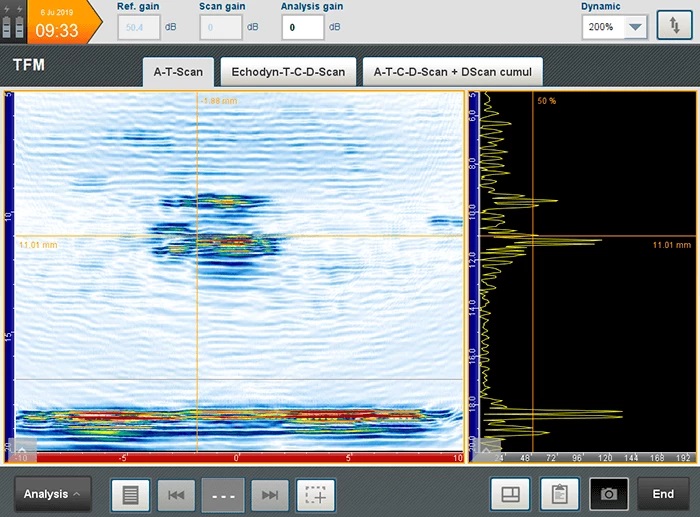

M2M Gekko is a field-proven flaw detector with PAUT, UT, TOFD and TFM capability. It has an optimized user interface called “Capture” that facilitates equipment operation. The equipment has different channel configuration options: 32: 128, 64:64 or 64: 128, Gekko combines high resolution and inspection speed in addition to reducing inspector training times.

Benefits

Applications

- Greater precision with high resolution images.

- Advanced defect analysis with the total focus method.

- Robust field unit with high battery life.

- Simple configuration with integrated inspection plans.

- Evolutionary software following inspectors’ comments.

- Inspection of damage by HTHA and hydrogen with TFM.

- Enhanced thick weld inspection and stainless steel / CRA weld inspection with 128 element aperture.

- Large area corrosion mapping (up to 5 × 5 m [16.4 × 16.4 ft] / 1 mm [0.04 in.] In steps).

- Dedicated complex geometry solution for pipe and fillet welds (Y and T joints).

- Weld inspection procedures with multi-group configuration.

Built for UT inspectors of all levels

With tools continually added in a separate application, “Capture” interface makes the inspection process easy and reduces operator errors.

No need to use third-party software to load basic and advanced procedures, UT inspectors of all levels have access to performance through a visual and guided interface. The “Capture” interface offers a quick way to improve knowledge and requires minimal training for phased array inspectors.

Gekko packs all the basic and advanced UT functions into a rugged compact housing designed for field use. The basic configuration features conventional UT, TOFD and all matrix UT techniques in beamforming phase for single beam and multi-group inspection, and its 3-axis coded capabilities make the Gekko ready for any inspection . This robust PAUT unit also offers real-time TFM / FMC (Full Matrix Capture) and adaptive TFM techniques.

Specifications

INSTRUMENT

Dimensions (W × H × D): 410 × 284 × 126 mm (16.1 × 11.2 × 5.0 in)

Weight (with 1 × battery): 6.4 kg (14.1 lb)

Power supply: 15 V, 5.67 A

Batteries (hot-swap capabilities): Types: 2 × Li-ion, 94 Wh capacity

Typical life: up to 6 hours

Display: 26.4 cm (10.4 in) resistive touchscreen

1024 × 768 px screen resolution

Storage: 256 GB SSD, expandable up to 1 TB

ENVIRONMENT

IP rating: Designed for IP66

Operating temperature: 10–45°C (14–113°F)

Storage temperature range:

w/ batteries: 20–60°C (-4–140°F)

w/o batteries: 20–70°C (-4–158°F)

Drop-tested: According to MIL-STD-810G

CONNECTIVITY

Fast gigabit Ethernet, Wi-Fi connection with USB dongle

1 × Micro display port

1 × IPEX PA connector

3 × axis encoder input

1 × USB 3.0, 3 × USB 2.0

LEMO® 00 UT connectors (4P/R)

I/O 12 TTL (5 V/24 V), 6 × open collectors

PHASED ARRAY

PAUT channel configurations: 32:128PR, 64:64PR or 64:128PR.

Active aperture up to 64 elements.

Linear, matrix, dual linear & dual matrix arrays.

Up to 8 beam sets | Up to 2,048 focal laws.

Linear, sectorial, compound scanning & CIVA-laws import.

CIVA-fueled phased array calculator.

True-depth, constant sound-path & projection focusing modes.

On-board focal law calculator on plates, pipes, fillet welds, nozzles.

FMC/TFM*

Real-time TFM up to 128 elements 256 kpi.

Refresh rate up to 110 Hz at 65 kpi.

Real-time adaptive TFM (ATFM)**.

All calibration wizards available.

Image resolution above 4 Mpi in post-processing.

Direct, indirect and converted modes.

FMC recording.

8 × manual resolution levels, 1 × auto resolution setup.

ACQUISITION

Hardware acquisition gates.

PRF up to 40 kHz.

Data flow on SSD up to 180 MB/s.

Live 3D/overlay display.

A-scan/peak data recording.

Data compression up to 32x.

Live data missed information.

Data file size: limited by SDD capacity.